Iron is easy to rust, so the cast iron cookwares are also easy to rust. In order to prevent the cast iron cookware from rusting, we usually pre-seasoned the cast iron blank or make an enamel coating. These are the most common coating for cast iron cookwares.

However, if the pre-seasoned cast iron fry pan is not properly maintained, it is easy to rust. In recent years, there has been a new technology – super pre-seasoned coating. It means the cast iron blank is nitrided first and then pre-seasoned. In this way, the rust resistance of the cast iron pan will be greatly enhanced.

What is nitriding treatment:

Nitriding treatment refers to a chemical heat treatment process in which nitrogen atoms penetrate into the surface of the workpiece in a healthy medium at a certain temperature. Nitrided products have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance.

How to Nitrid a Cast Iron Pan:

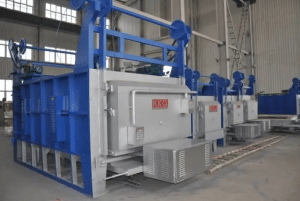

Usually, we put the cast iron blank into the nitriding furnace according to a certain density. After 8-9 hours of nitriding treatment, we will get the nitrided blank . At this time, there will be a certain amount of iron filings on the surface of the blank, which needs to be cleaned with a vibrating grinder

After pre-seasoning the clean blanks we will produce the nitrided pre-seasoned cookware, which is greatly enhanced in rust resistance.

Vibrating Grinder Nitriding furnace