Cast iron cookware is a common kitchen cooking item that you can easily buy on Amazon or Walmart. Below we will describe the production process of Chef-cookwares‘ enamelled cast iron pans.

1.Raw Materials

The raw materials for of cast iron pots are mainly bread iron and some steel, which is smelted into molten iron in an industrial electric furnace, as shown in the figure below.

Bread Iron Melting

2.Melting&Casting

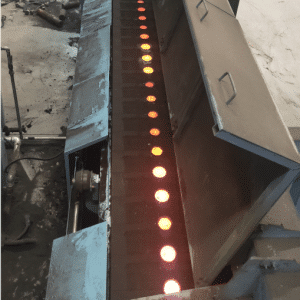

After the molten iron is qualified, pour it into the sand mold, the molten iron flows to every corner of the sand mold under the action of gravity. As the DISA production line goes on, the molten iron is gradually cooled and formed, then the sand and the blank are separated by a vibrating screen.

3.Polished

Wash the blank with steel balls for the first time to remove the excess sand on the surface and make the surface smooth.

Use a high-speed rotating grinding wheel to remove the burrs of the blank.

Use finer steel balls to clean the surface of the blank to make the surface of the blank smoother and meet the requirements of enamel.

Molten Iron Cooling Steel Ball Cleaning

4.Enameled

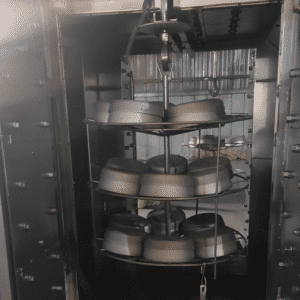

When we get the qualified blanks, they will be transferred to the enamel workshop

Enameled: after spraying glaze and high temperature, we will get the final enamel product. After quality inspection and audit, qualified enameled cast iron pans will be shipped to the packaging workshop for packaging and the final product will be obtained.

Coating Baking